Who we are

Dear Customers,

Sip-Italy is a division of our company TOR.MEC AMBROSI Srl specialized in the development and production of automatic units for Jeans & Trousers.

Our passionate team has more than 40 years of working experience in this field. Our plant is located in Verona, north of Italy. We focus on “A top class” apparel industries, interested in the best product of engineering, quality and daily production output. We achieve the goal to manufacture friendly use automatic work-stations, with the best ratio in terms of productivity and versatility at the lowest running cost. Most of our automatic workstations are equipped with common electronic hardware and standard sewing heads.

It is the unique technical solution that guarantees the real after-sales service and consequentially the R.O.I.

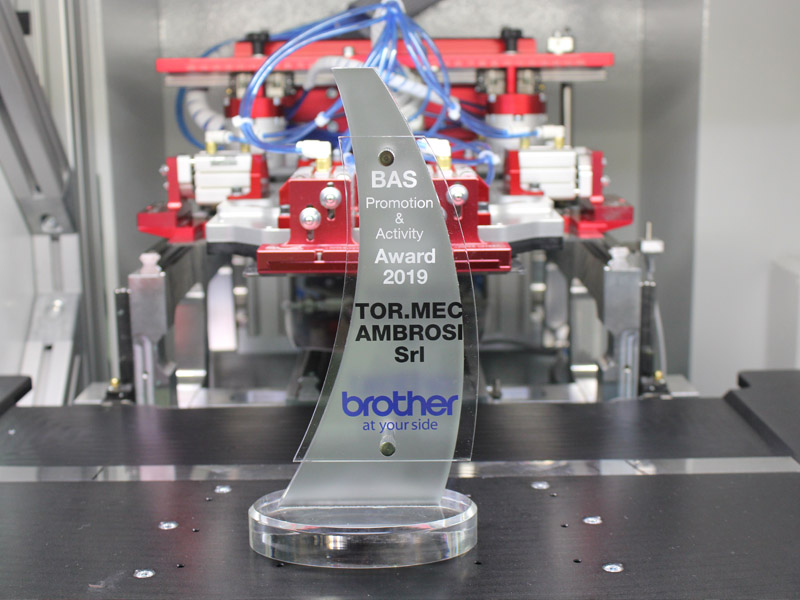

The best products made with the best supply chain! This is one strength of our business strategy. Thanks to management’s credibility and reputation, we are proud to have successful technical cooperation with the major Japanese sewing machine manufacturing companies in this field.

New green jeans factory!

Sip-Italy, in cooperation with our distributors, is actually the best proposal for complete turnkey solutions for a new green jeans factory, really matching the concept of Factory 4.0, the actual benchmark for all Industries.

This kind of total turnkey solution is a mix of the best-advanced technology and garment production know-how: we are a total solution provider, not simply a machinery manufacturer, providing smart projects totally integrated with our own technology.

Indeed, at the date of today our company Group is the unique who can provide under the same umbrella game-changing technologies:

1. the design & engineering of the production process of the entire factory, from cut to pack

2. automatic sewing units and robotic workstation solutions

3. handling automation as trolleys and stacker devices

4. factory production know-how, implementation and set up with a skilled organization chart

5. sewBI business intelligence software and hardware for data control of the pro¬ductivity and the efficiency of the machinery, operator and much more.

6. ONO Lean Logistics storage technology

7. maintenance and management machinery software

We hope that you’ll enjoy discovering a new state of the art of Apparel Industry.