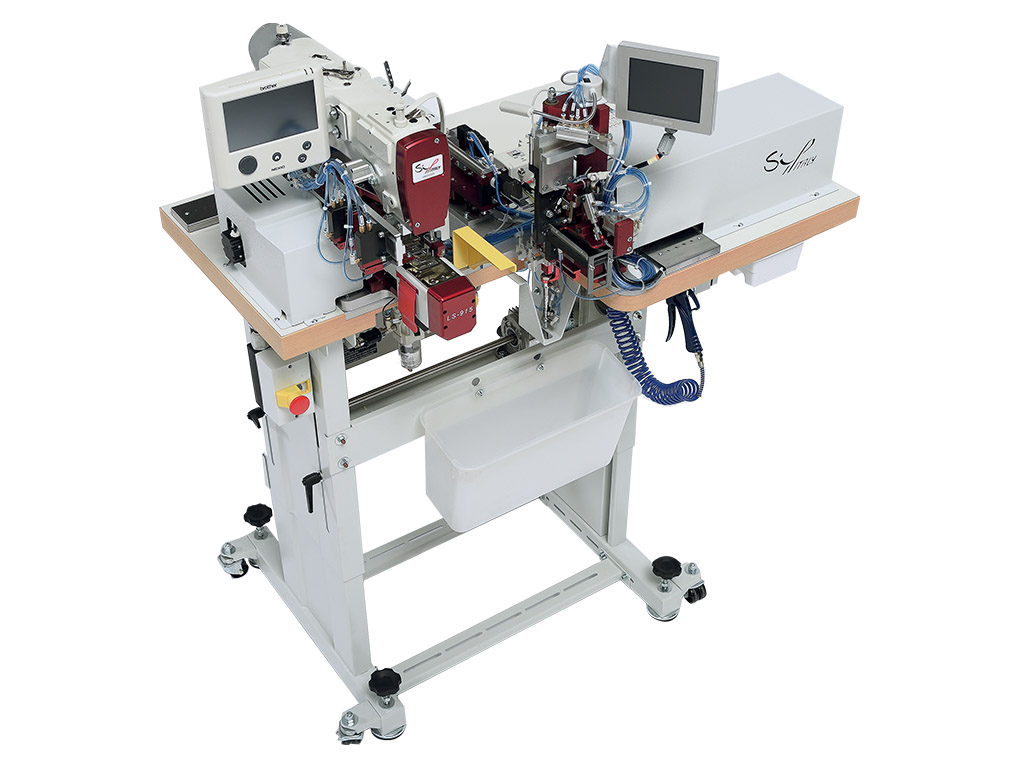

LS915H-EV2

AUTOMATIC PROGRAMMABLE BELT LOOP SETTER UNITHighlights

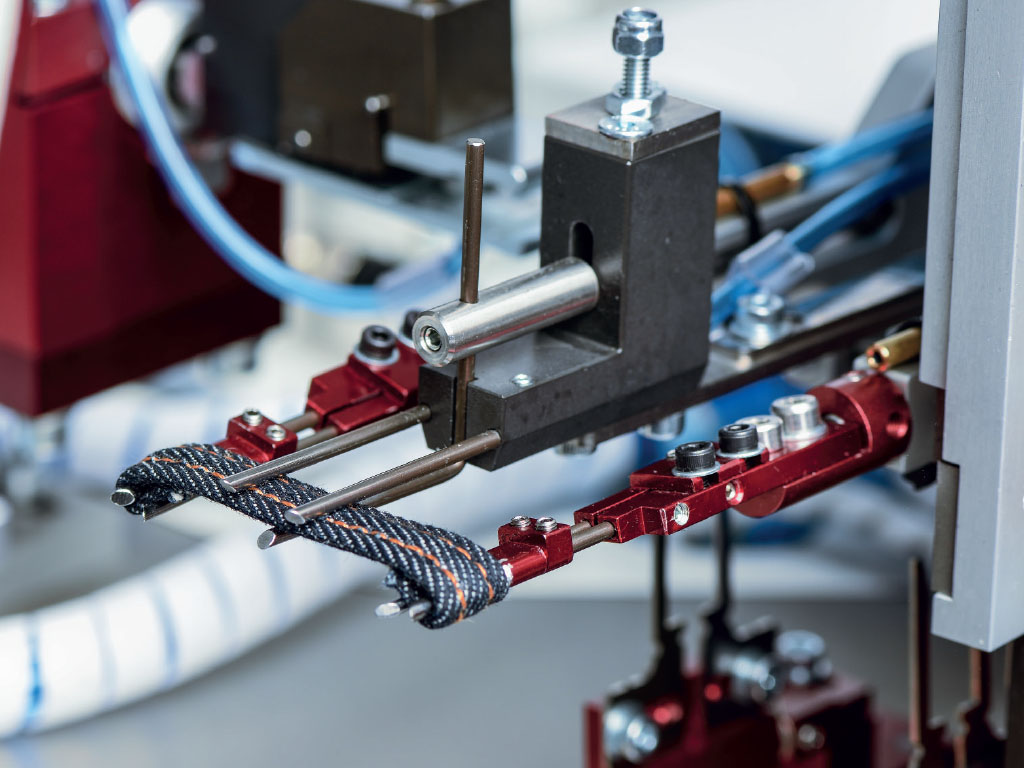

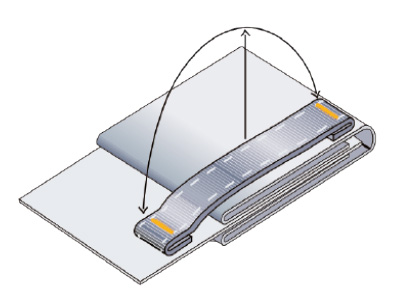

Automatic programmable belt loop setter unit for cutting, folding and attaching the patch loop in one operation. The user is able to use the unit for all kind of fashion trousers design with variations of sewing program and kind of loop, inserted or patch.

The customer does not achieve the R.O.I. only by productivity, the user absolutely needs the flexibility of use for fashion garments, a fast easy change for different garment styles, programming on laptop thus saving production time, having parts available locally. The real production world is fashion and small order run. It means to have more garments coming from different lines to the Belt Loop attaching operation area.

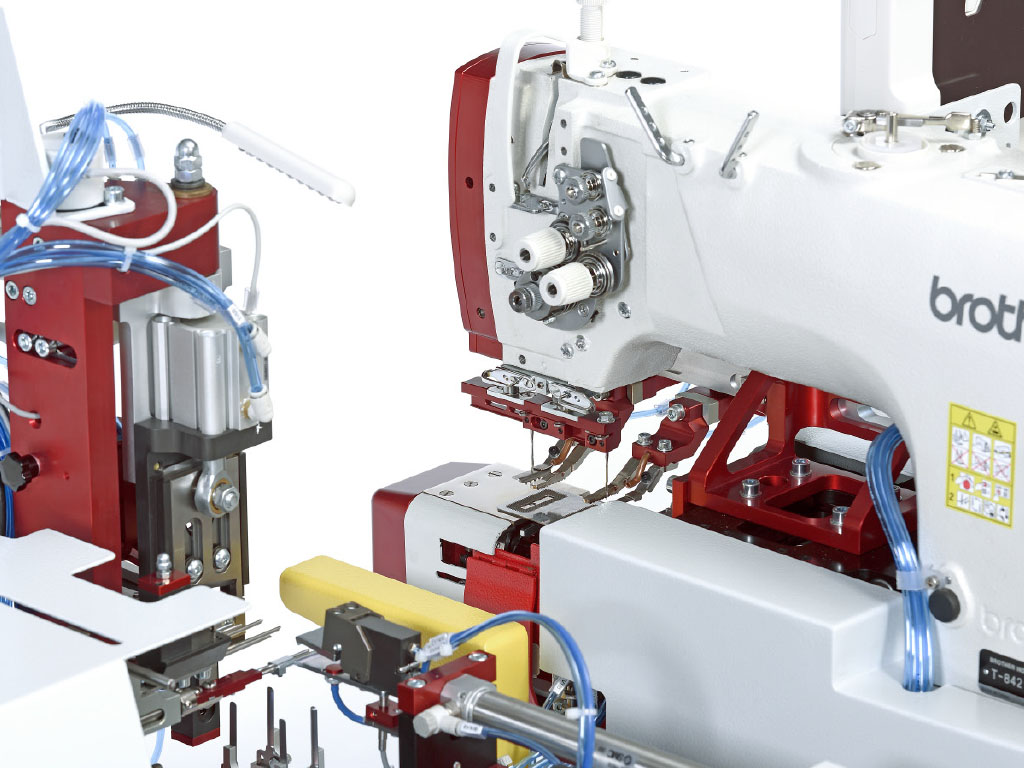

- Kids wear: the smallest double needles sewing head arm in the market suitable for small size pants

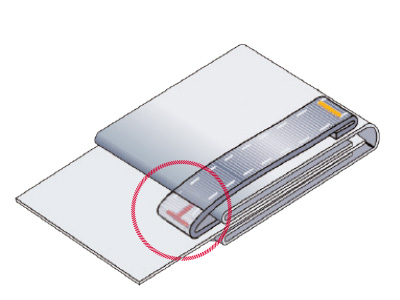

- The Clean cut drastically reduces the production cost! No more helpers to cut manually the loop edge sides after attaching

- Wider space between sewing head and loader for better handling and garment rotation

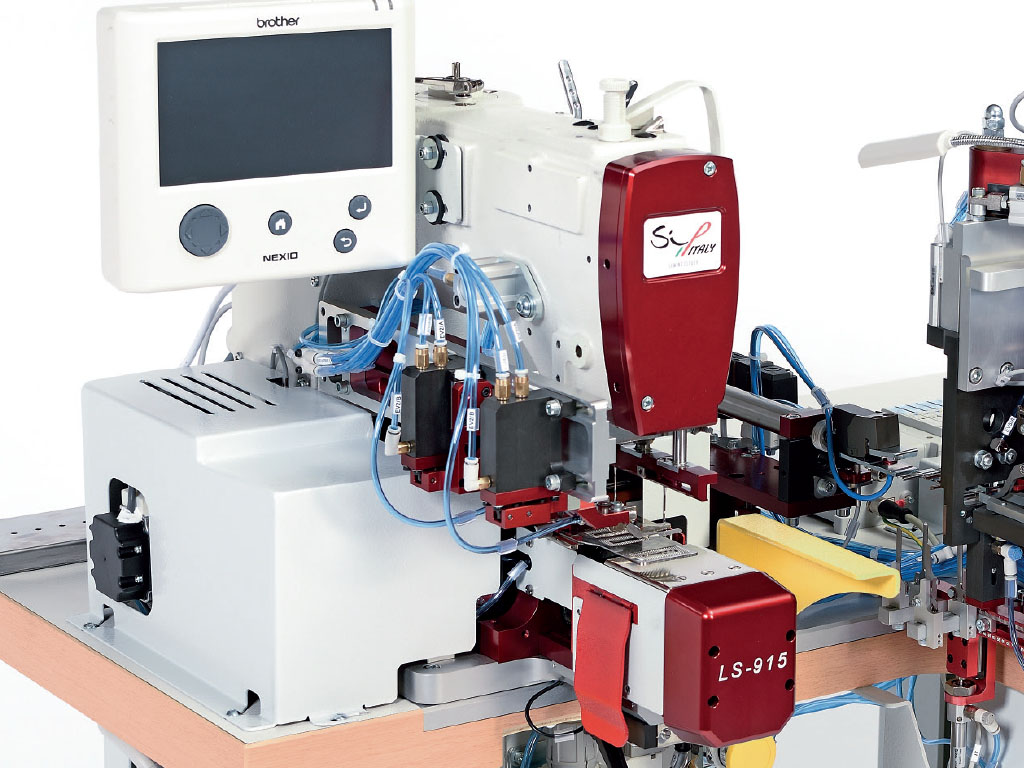

- Unique two needle loop setter unit equipped with double needle bars: more sewing strength and more versatility!

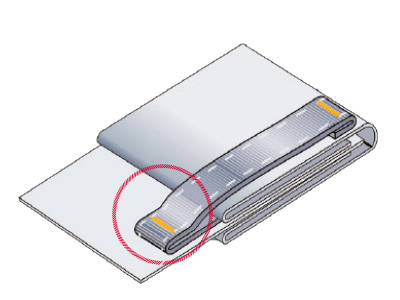

- Smart loop joint detector device with shortest wasted fabric length

- Compensatory presser feet with double pressure logic function

- IoT Software for FACTORY 4.0 for cloud connectivity of production data, error message, software update, remote control and more

- Ready for sewBI: our business intelligence revolutionary platform by Sip-Italy. sewBI is business intelligence applied into sewing dept., the unique technology able to combine and collect all production details by machinery and operator efficiency together with work in progress status of the production lot

Technical Data

Standard SettingSewing Head

Direct drive Brother model T-8720, double needle lock stitch, large rotary hook size

Max sewing speed

2.800 RPM

Average production with 5 loops

200 pairs /1 hour

Weight of the workstation

245 Kg (only workstation)

Measure of the workstation

125 x 95 x 140 cm

Air consumption

1.5 Liter/cycle at a pressure of 5.5 bar