PH100 SERIES

AUTOMATIC POCKET HEMMING UNITHighlights

The unit is suitable for all kinds of fabric, from super stretch denim fabric to heavy work-wear material, equipped with adjustable folder as standard, the workstation is already prepared for sew-BI, the factory 4.0 productivity data connectivity as the most mandatory requirement by open-minded customers.

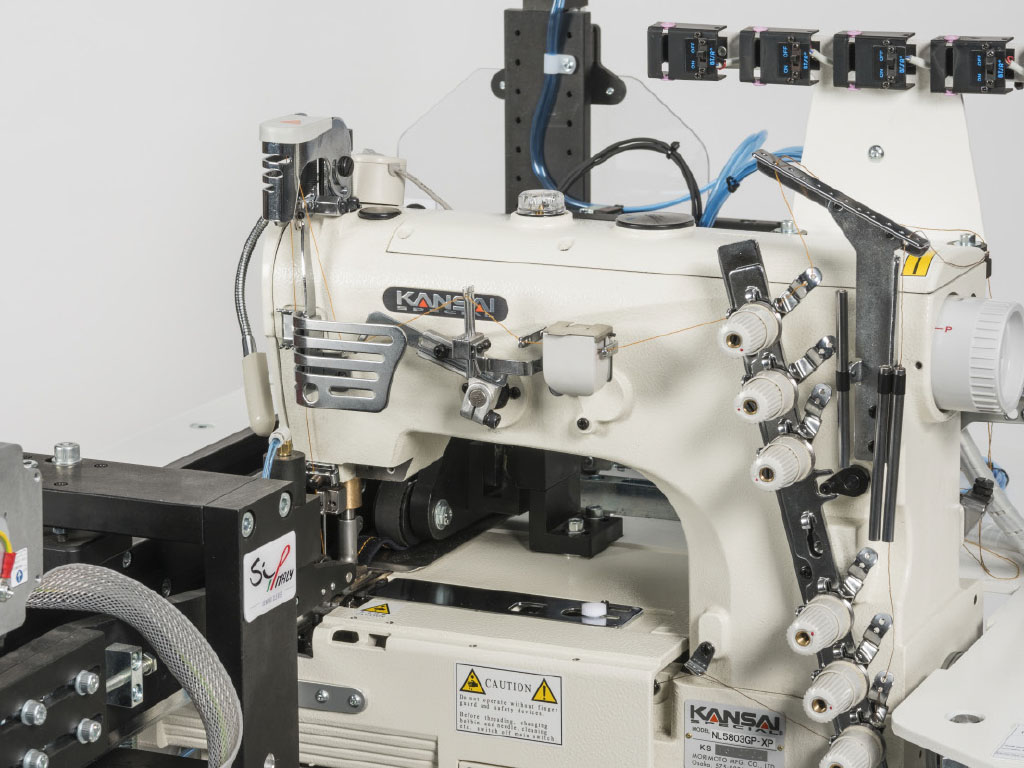

PH100CH-SIP: equipped with standard three needle chain stitch sewing head, made by Kansai.

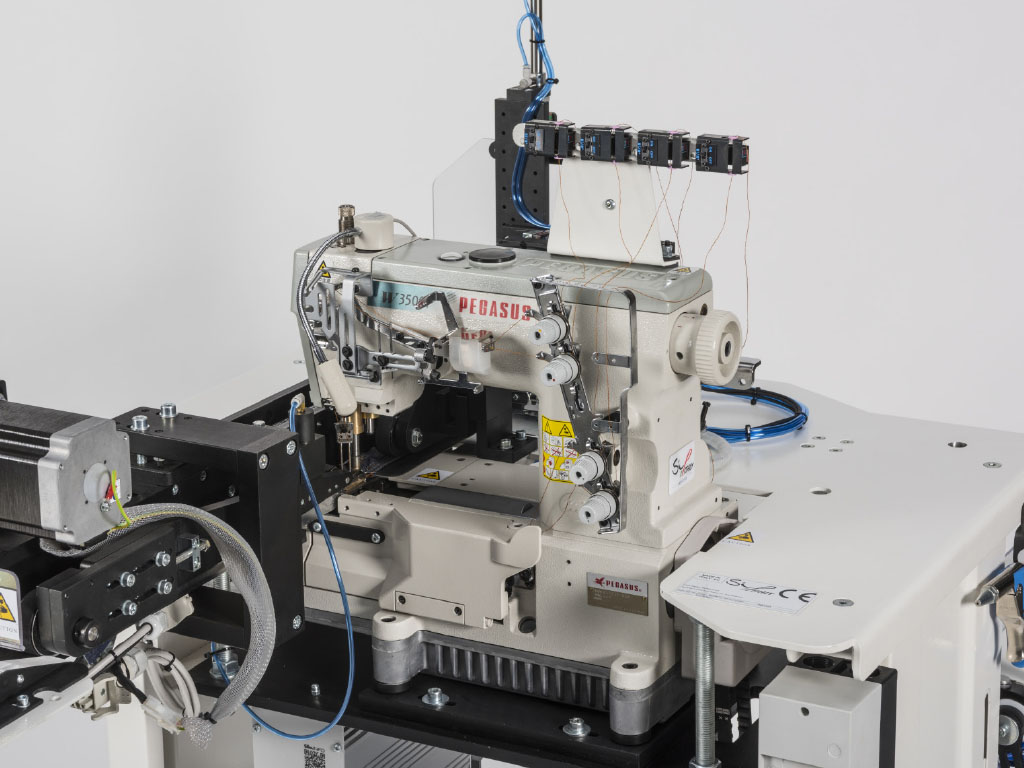

PH100PGCH-SIP: equipped with standard two needle chain stitch sewing head, made by Pegasus.

PH100LS-SIP: equipped with standard two needle lock stitch sewing head made by Brother.

- Top productivity!

- Auto feeder robot device on demand available for production without operator unit model RPH1-SIP

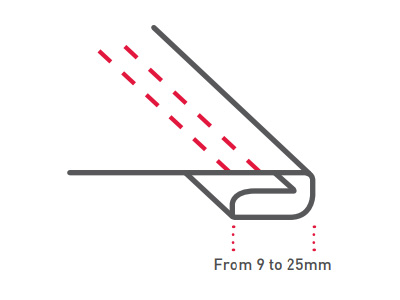

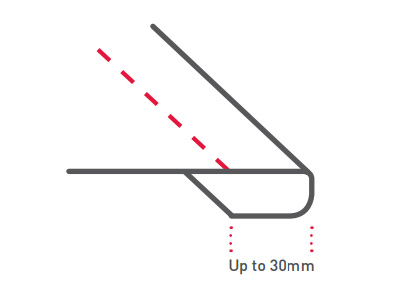

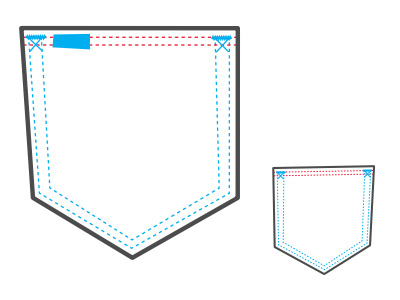

- Adjustable folder up to 25mm

- From light to heavy fabric! No curves! No waves!

- Common hardware and software as other automatic units

- Easy maintenance and set up

- Ready for sewBI: our business intelligence revolutionary platform by Sip-Italy. sewBI is business intelligence applied into sewing dept., the unique technology able to combine and collect all production details by machinery and operator efficiency together with work in progress status of the production lot

Technical Data

Standard SettingSewing Head

Unit model PH100CH-SIP Kansai model NL 5803GPXP

Unit model PH100PGCH-SIP Pegasus model W3522P-04BX264

Unit model PH100LS-SIP Brother model T8720C-005-N64D

Max sewing speed

3.000 RPMStandard Needle Gauge: 1/4” = 6.4mm

Production

Average production:

Chain stitch 2000 pockets-1000 pairs/1 hour

Lock stitch 1800 pockets-900 pairs/1 hour

Weight of the workstation

255 Kg (only workstation)

Measure of the workstation

147 x 100 x 156 cm

Air consumption

0,8 liter/cycle, pressure 5.5 bar