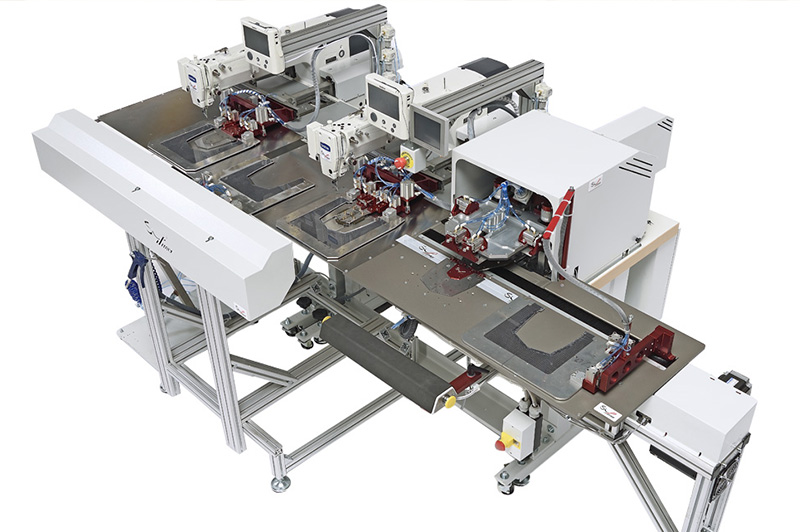

PS342-FG2SIP.V2 / PS342-RFG2SIP.V2

FULLY AUTOMATIC PROGRAMMABLE POCKET SETTER UNIT FOR JEANS & PANTSHighlights

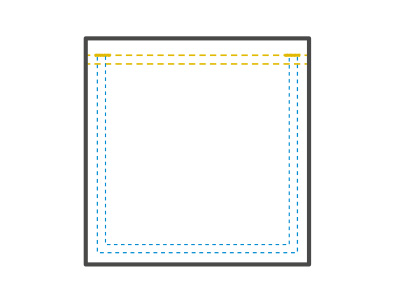

Automatic workstation for pocket folding and attaching in one operation.

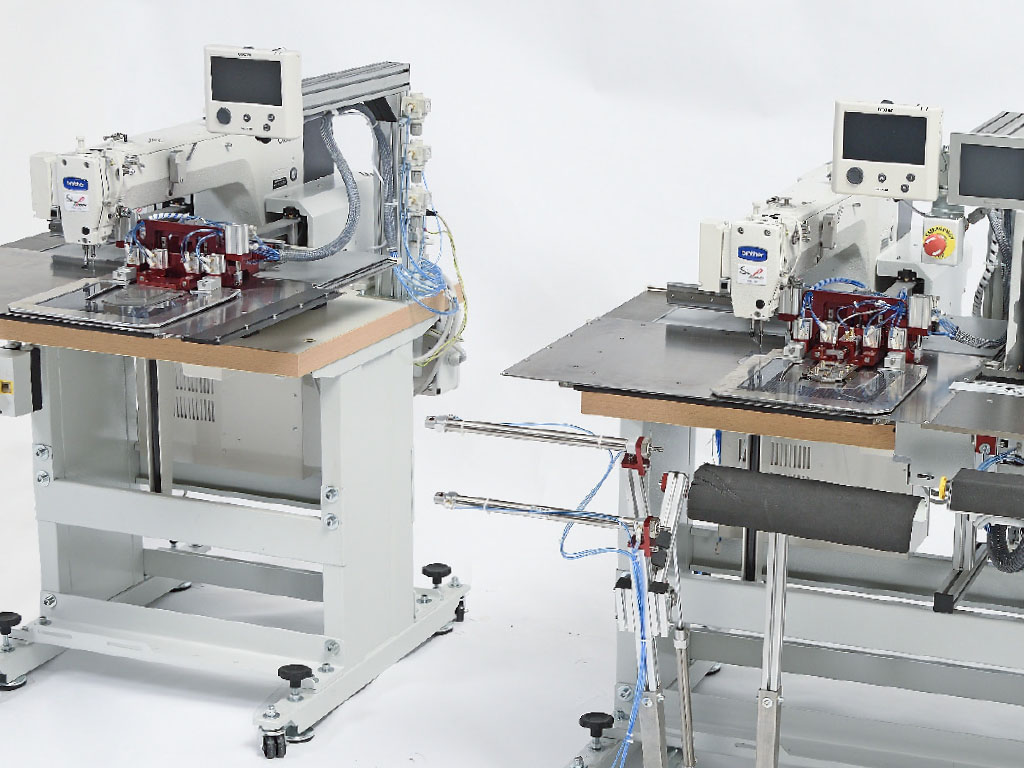

The user doesn’t need to utilize any pocket pressing unit. The two sewing heads work at the same time and give the opportunity to stitch a pocket with two different color threads for needle and bobbin case.

PS342-RFG2SIP: Unit equipped with patented 4-steps smart loader function device to perfectly balance the handling operator time. This avoids downtime between operations and increases production efficiency by 20% compared to the standard PS342-FG2SIP.V2 model

- Extra productivity of 20% compared with single head pocket setter unit

- Two sewing heads give the opportunity to stitch a pocket with two different colour threads for needle and for bobbin case

- Local pocket jig production by user in all countries of the world

- Automatic device for quick pocket jig change

- Multicolor touch screen 5.6"

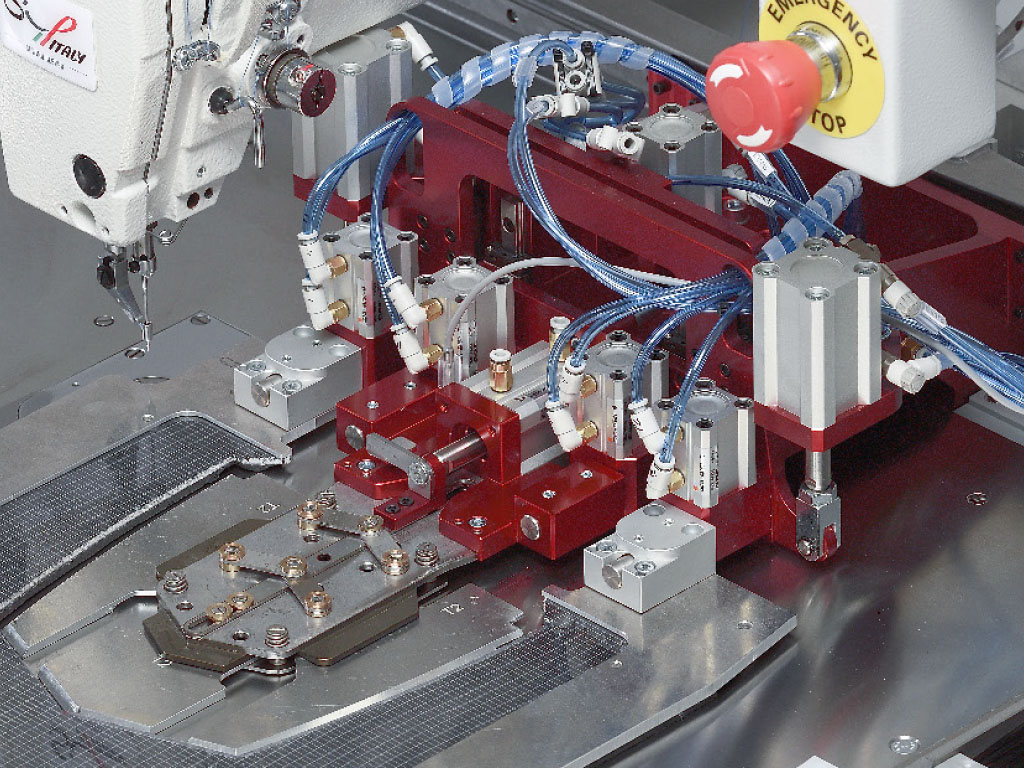

- All standard pneumatic valves and cylinders by SMC

- Lowest running cost!

Technical Data

Standard SettingSewing Head

2 (two) Brother model BAS-342 H Series, NEXIO Technology, single needle lock stitch, direct drive

Max sewing speed

3.000 RPM up to the stitch lenght of 3.5 mm.

Production

Average production:

PS342-FG2SIP.V2 150 pairs/1 hour

PS342-RFG2SIP.V2 180 pairs/1 hour

Weight of the workstation

750 Kg (only workstation)

Measure of the workstation

290 x 170 x 140 cm

Power supply

220 Volt, mono-phase 50/60 Hz